Palax C751: inspired by customer feedback and innovations

Palax firewood processors have become known over the decades for their speed, safety, and durability, particularly in the realm of mechanical-hydraulic circular saw machines. Now, Palax’s product development has taken a step into a new era of smarter solutions: the C751 firewood processor combines cutting-edge technology with user needs, making the machine even easier to use and maintain.

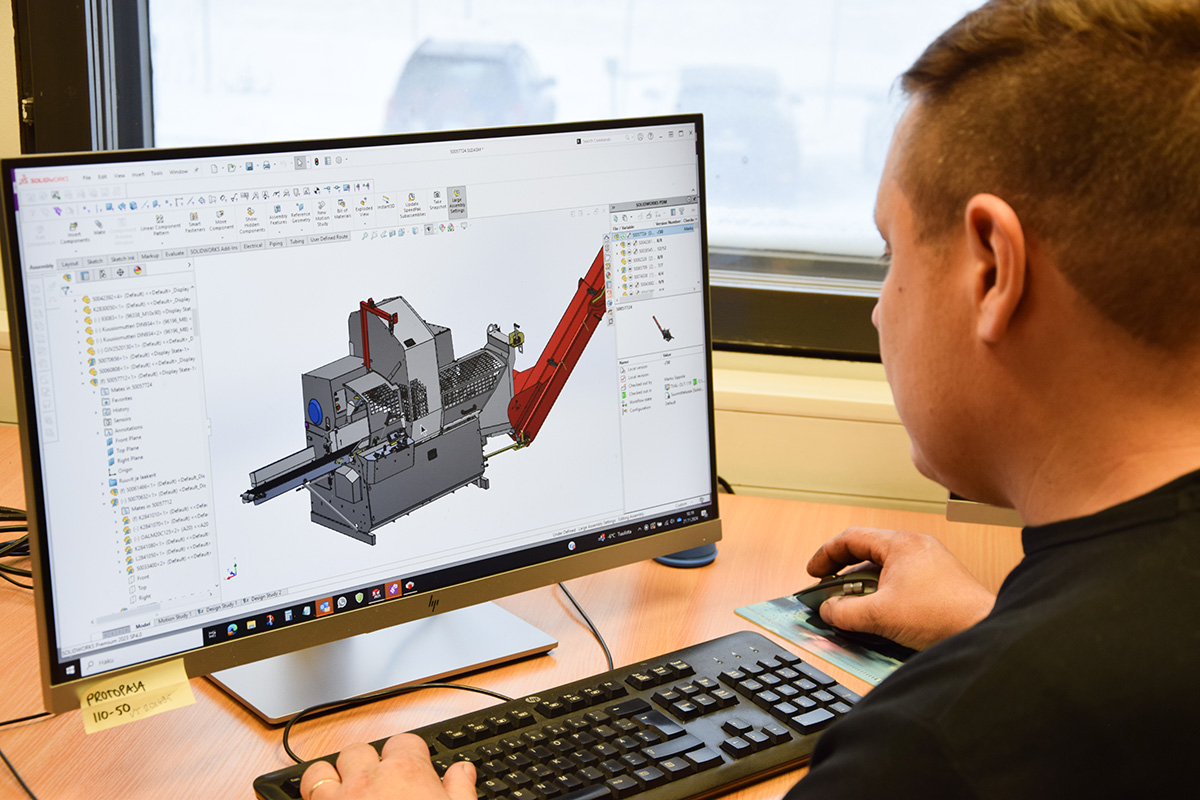

“It was challenging to improve upon the previous generation of machines. Feedback from our customers has been key in developing the new Palax C751 firewood processor. We have carefully listened to their experiences and challenges and sought solutions to further enhance the machine’s usability,” says product designer Marko Sippola, who has worked with Palax machines in various roles for nearly 25 years.

The return of logic control

Palax has previous experience with logic-controlled firewood processors, dating back to the TSVe Combi in the 1990s and the Palax Monster in the early 2000s. While these machines were ahead of their time, their production run was relatively short in the factory’s history. Now, over 20 years later, Palax is reintroducing logic control with updated, carefully chosen components and more advanced solutions.

Sippola highlights that the return of logic control in the C751 Smart and Pro+ models brings several advantages.

“Logic control enables auxiliary functions that simplify machine use and enhance safety while reducing the need for maintenance. In practice, this means that the operator doesn’t have to worry about in-use adjustments, allowing work to remain efficient throughout the day.”

Prioritizing an even better customer experience

In designing the new generation of machines, customer experiences with the predecessor of the Palax C751, the Palax Power 70, were carefully considered. According to Sippola, the Power 70 is already an excellent machine, serving as the foundation for the long-marketed Palax C750 and C750.2 models.

“One key piece of feedback was related to logs bouncing in the splitting groove, which caused feeding errors and unnecessary opening of the safety cover. The solution was a new geometry for the splitting groove, which also reduces the need for splitting force and improves cleanliness in the splitting area. This, in turn, allows freer movement of the splitting blade and enhances the precision of the X-Aim system.”

Another essential improvement is the structure of the log stopper. The previous stopper could flex when logs were fed from the conveyor, causing the logs to bounce back onto the conveyor. The new stopper has shorter, sturdier blades and is more reliable. It allows the blade to cut the log at exactly the right spot without getting stuck, and the stopper automatically moves aside as the blade moves down.

Several other significant mechanical improvements have been made in the Palax C751. The machine is now sturdier, with a weight increase of over 200 kg. An additional rear support further reduces the load on the splitting blade, and extremely durable Hardox blades with a new geometry are now used. Furthermore, the log length has been adjusted: a customer request to reduce the minimum log length from 25 cm to 20 cm has been incorporated.

“Now, the machine structure allows for producing shorter 20 cm firewood, which is a standard length in the UK. For logs shorter than 30 cm, the new half-stroke function can be used, significantly reducing the cycle time.”

Innovations for easier usability

The Palax C751 Smart model also includes features that customers didn’t specifically request but that enhance the user experience in entirely new ways. The in-feed assist is one of these innovations.

“The in-feed assist is a major change. It enables an automated work cycle: when the cutting button is held down, the cutting blade cuts the log. Simultaneously, the X-Aim centers the splitting blade, and when the cutting button is released, splitting begins automatically. At the same time, the log is moved on the in-feed conveyor for the next cut, starting the new cycle with the cutting button,” explains Sippola.

The X-Aim 2.0 technology in the Smart model, which positions the splitting blade in the center of the log, uses more accurate sensors and no longer requires separate calibration or specialized splitting blades.

Additionally, Sippola highlights the Smart model’s new graphic display, which provides productivity data, notifies the user of maintenance needs, and assists in troubleshooting.

“Settings can be adjusted and counters monitored on the display. The machine will notify the user, for example, when it’s time to change the hydraulic oil. The display also makes troubleshooting much easier, reducing downtime.”

Don’t forget proper storage

Durability and quality have always been cornerstones of Palax firewood processors. The Palax C751 has been more thoroughly tested at the factory and by trusted customers than any previous model, with production-level testing involving hundreds of cubic meters of firewood. Feedback has been exclusively positive.

All machine components have been carefully selected to withstand demanding conditions for decades, including extreme temperature fluctuations in summer and winter.

“While our machines are exceptionally durable, we still recommend keeping them protected and preferably stored indoors. This minimizes damage from harsh conditions, extends the machine’s lifespan, and helps maintain a high resale value,” Sippola reminds.

Marko Sippola was responsible for the product development of the Palax C751 machine.

Sippola visits the production lines where the C751 machines are being manufactured.

See also