Looking forward to continuing many more years of loyalty with Palax

I & A Woodliffe (Yorklogs) from York, northeast England, is a family run business with 20 years of experience in supplying wood and wood products. Ian Woodliffe works full-time running the business and making and delivering logs. Amanda Woodliffe, Ian’s wife, works part-time keeping the paperwork up to date and bagging net logs with one part-time employee who splits timber into logs.

Ian and Amanda sell nets of logs for customers to collect and supply several farm shops. “We also deliver loose loads of logs in the local area and have a good client base with lots of regular customers that have been with us for many years. All our offering is now air-dried hardwood.” The couple started selling logs 20 years ago as it was the only way to get rid of the timber from their tree surgery business; if they didn’t turn it into logs to sell they would have have had to pay to dispose it.

A long history with the Palax machines

For the first two years, Ian and Amanda cut everything up with a chainsaw and axe which was a lot of hard work. “In the third year, we bought an Italian PTO driven bancho splitter and a PTO driven Palax Logger saw blade cross cut with elevator, which we used for approximately 4.5 years as we increased tonnage.”

A firewood processor was needed when they were starting to buy timber in and processing around 400 tons of timber per year. Ian and Amanda were already familiar with the Palax brand and their friend was running a Palax Combi, so this helped the decision to go for a PTO driven Palax KS 35 after talking to Jim Watt, the former UK importer for Palax, who they met him at the APF Exhibition, the UK’s largest forestry and woodland show. “We bought the show demonstrator which Jim delivered to us on his way home from the show. This machine served us extremely well, met all our needs and kept on top of the job regards the tonnage.”

After 7 years, it was time for an upgrade and the same sized processor was all they needed. “We chose the KS 35S which was a pleasant increase in overall speed and went for the 3-phase option which is much quieter for the operator to use. We’ve really enjoyed the power and speed of the KS 35S, which in return has helped us with ease move to processing up to 600 tons of timber per year, and we only process 2-3 days a week in the summer months.”

More splitting force and speed with the new Palax D410

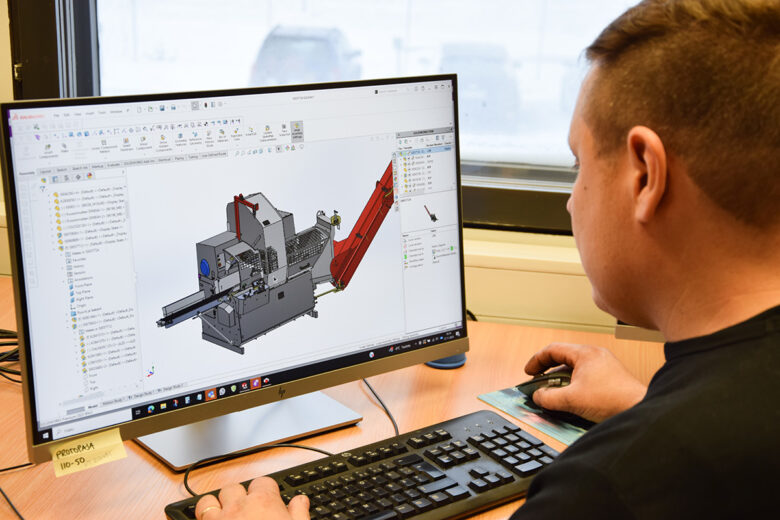

In 2020, Ian and Amanda decided to change over from KS 35S to the new Palax D410 Pro+.

“We needed more splitting force without losing any speed. The D410 was the obvious choice with 13 tons of splitting power and certainly the same speed on the 6” down timber, but an increase in speed over all with 8” upwards due to been able to operate with the 8-way knife.” They admit the machine would help them to increase production tonnage per year if needed, but they are just happy to have the processor to be completely on top the job.

Both Ian and Amanda have been extremely happy with Palax firewood processors and the service from their UK dealer.

“We have been loyal to Palax now for almost 20 years as we feel loyalty is important to a company, especially if you want an excellent service in return. You can’t have one without the other. The service we have received from Palax dealers has been superb, and we look forward to many more years of loyalty and service to come.”

See also